- +86 18825289328

- support@hiwonder.com

- Home

- All Products

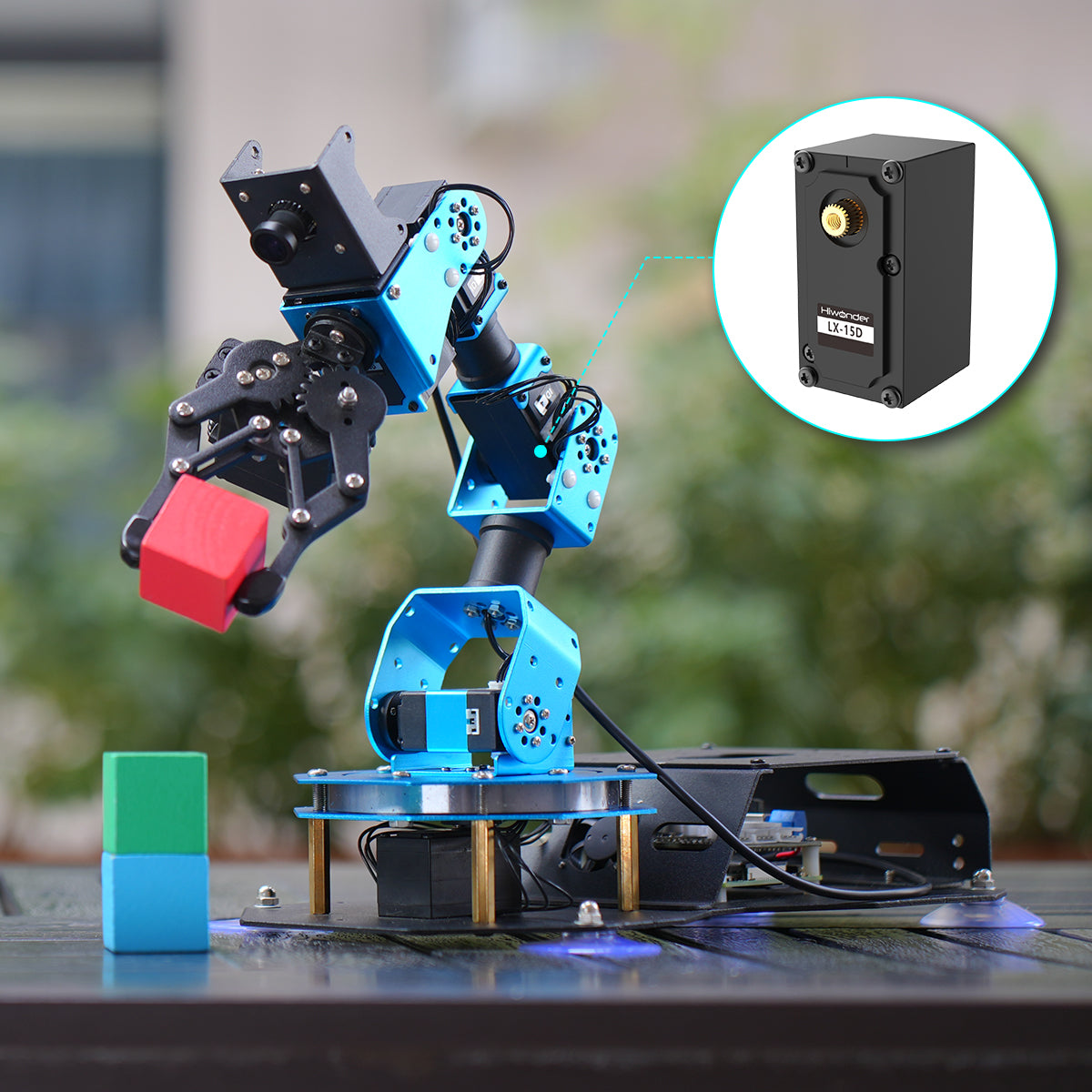

- Hiwonder LX-15D Intelligent Serial Bus Servo with RGB Indicator for Displaying Robot Status Hiwonder LX-15D Intelligent Serial Bus Servo with RGB Indicator for Displaying Robot Status

Hiwonder LX-15D Intelligent Serial Bus Servo with RGB Indicator for Displaying Robot Status

- Torque for LX-15D servo: 15 kg/cm (208 oz/in) 6V; 17 kg/cm (236 oz/in) 7.4V

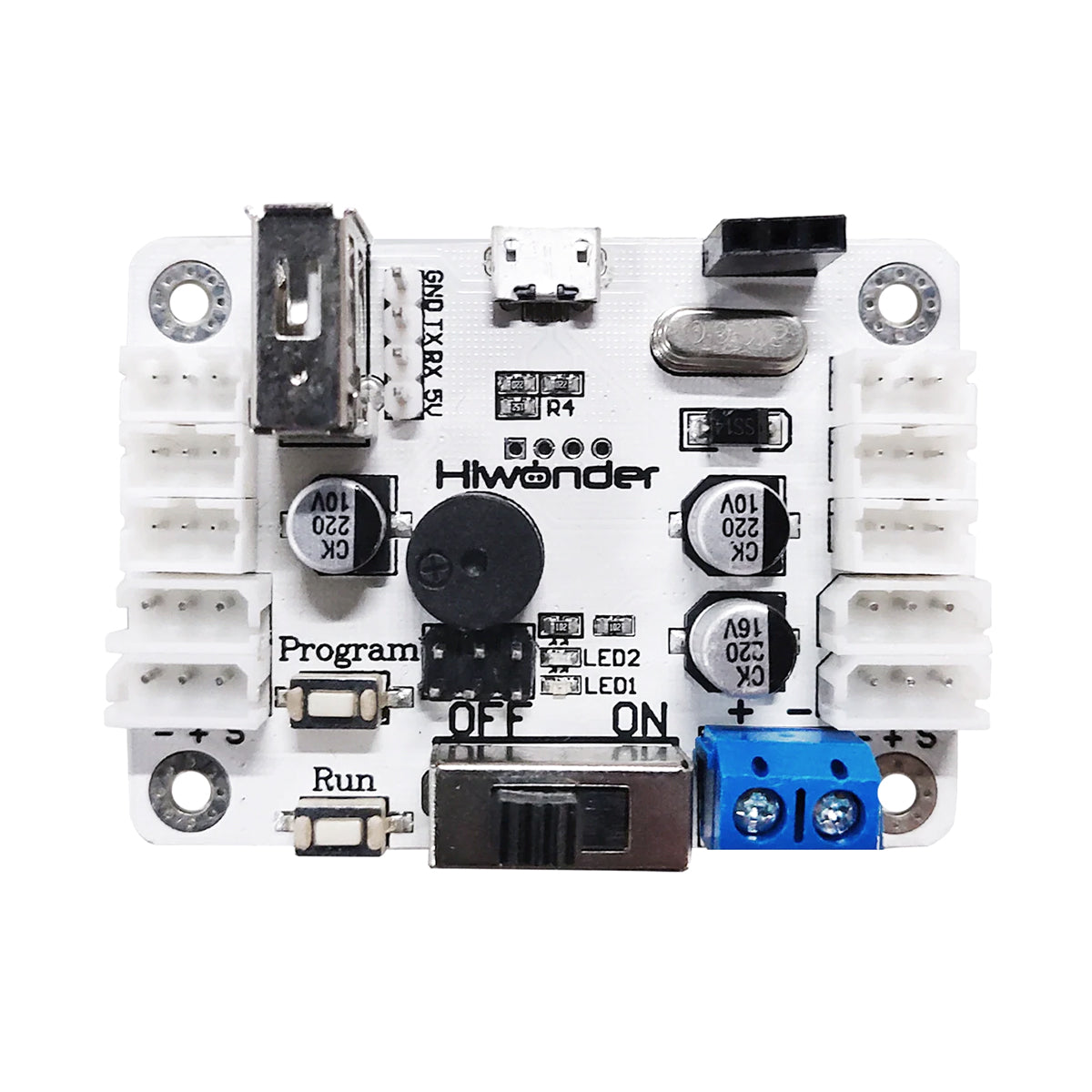

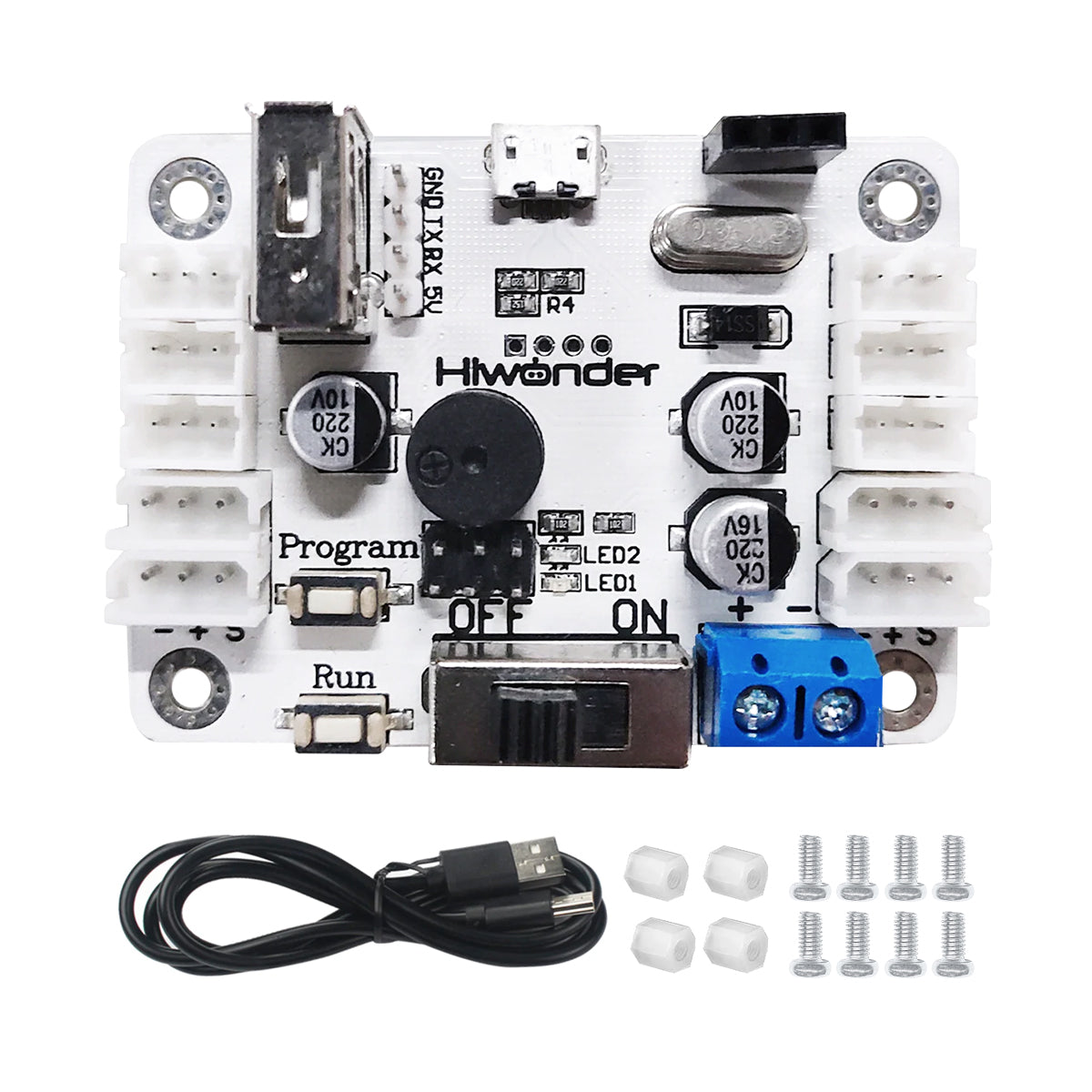

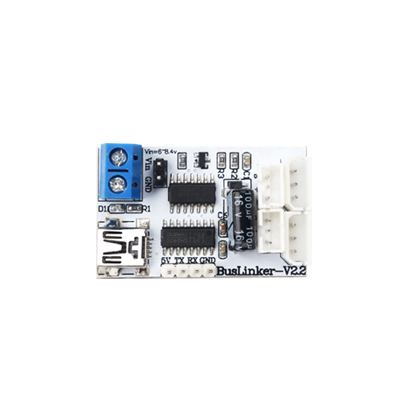

- TTL / USB tester board is a servo debugger, which is able to connect the servo to the PC software or other devices and use them to adjust the parameter of servos

- Bus servo controller can be used in serial servo control and it can combine with PS2 wireless handle to realize servo remote control

- Details Tutorial: Provide bus servo communication protocol, 51 Arduino and STM32 source code

- Description

- Specifications

- Accessories

Product Description

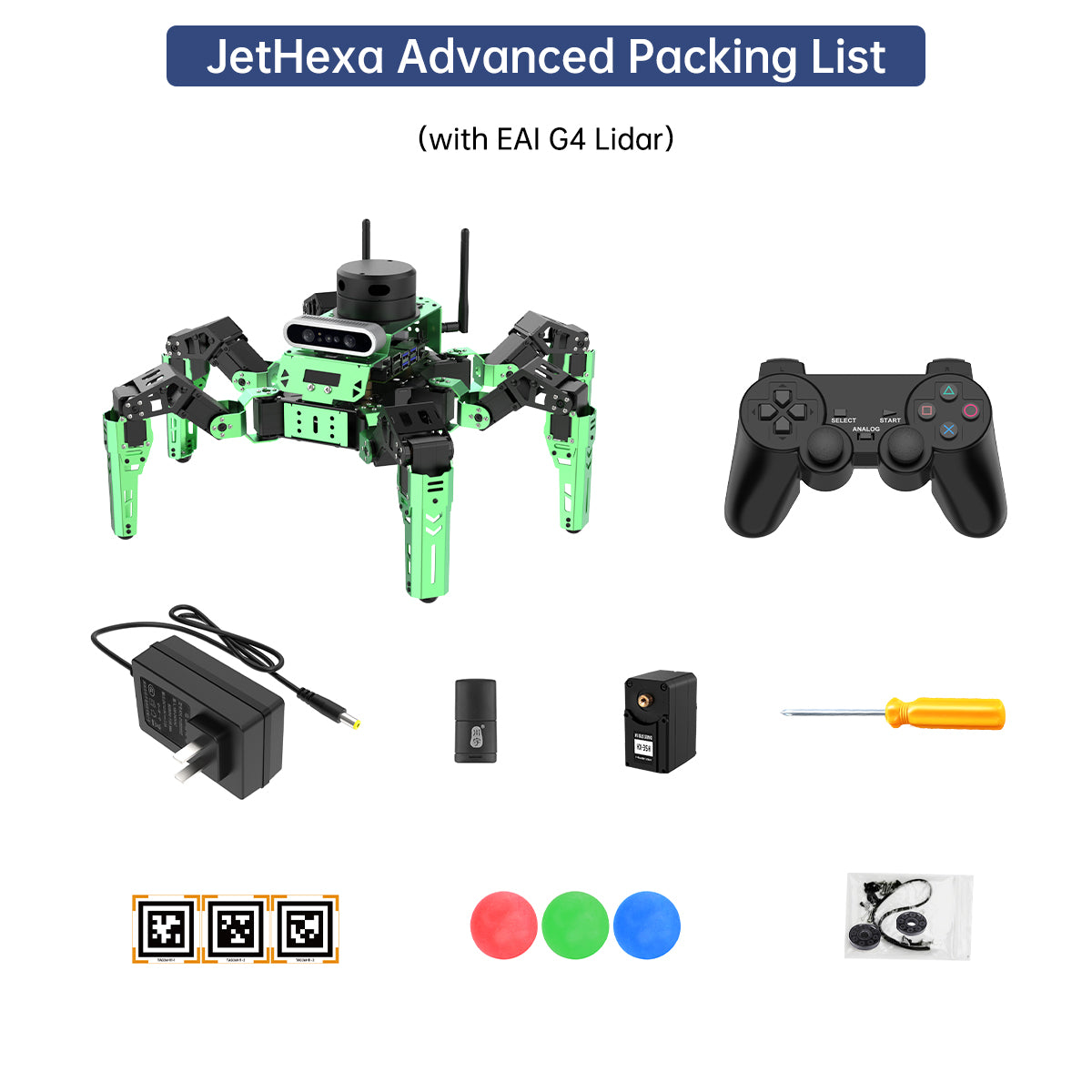

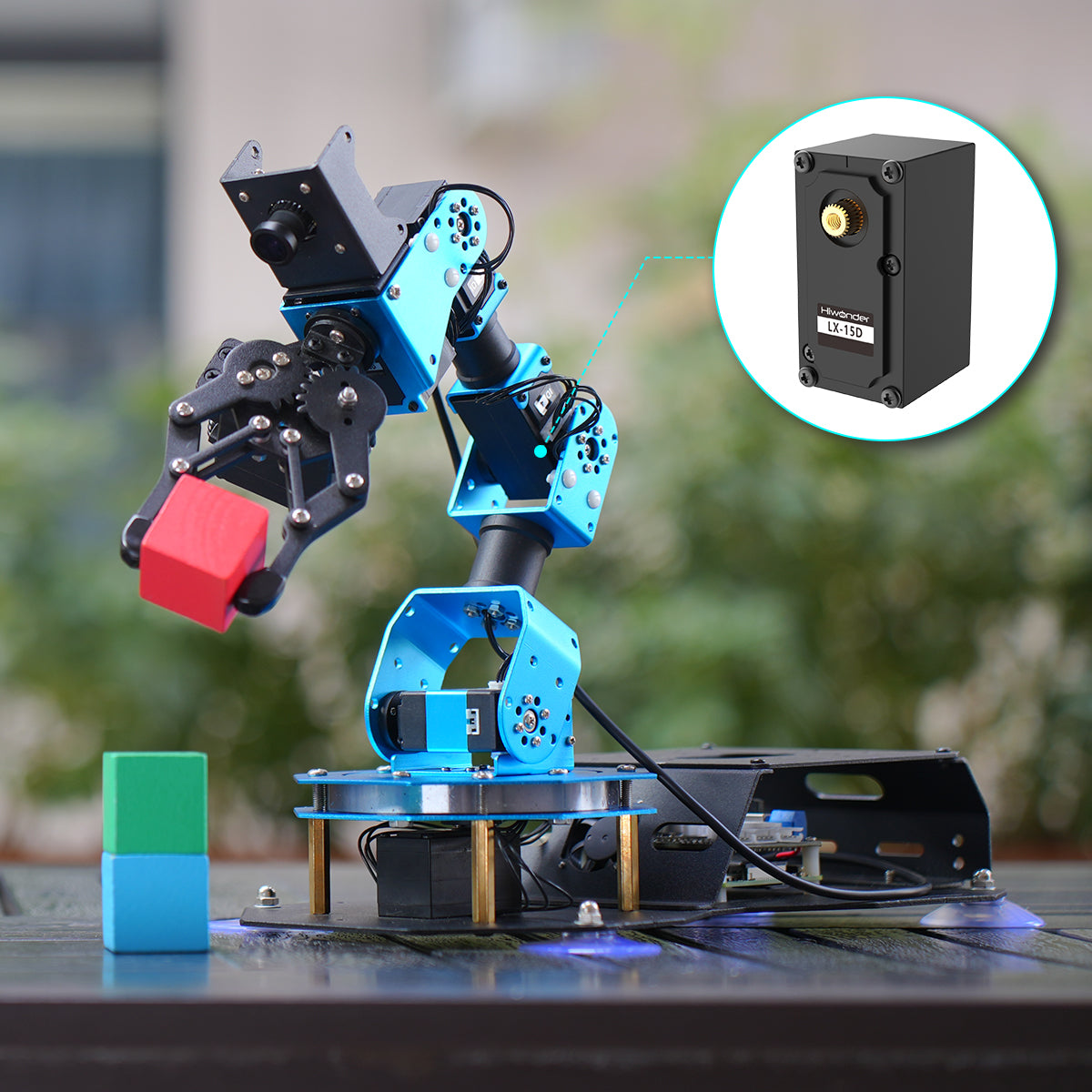

LX-15D is a full metal gear serial bus servo with high torque. It can provide temperature, position feedback. LX-15D Bus Servo uses our private serial protocol so that it is necessary to use our TTL/USB debug board (compatible for Arduino) to control bus servo.

Packing List

- 1*LX-15D servo

- 1*Plastic main servo horn

- 1*Plastic assistant servo horn

- 1*Servo wire(200mm)

- 1*Screw package

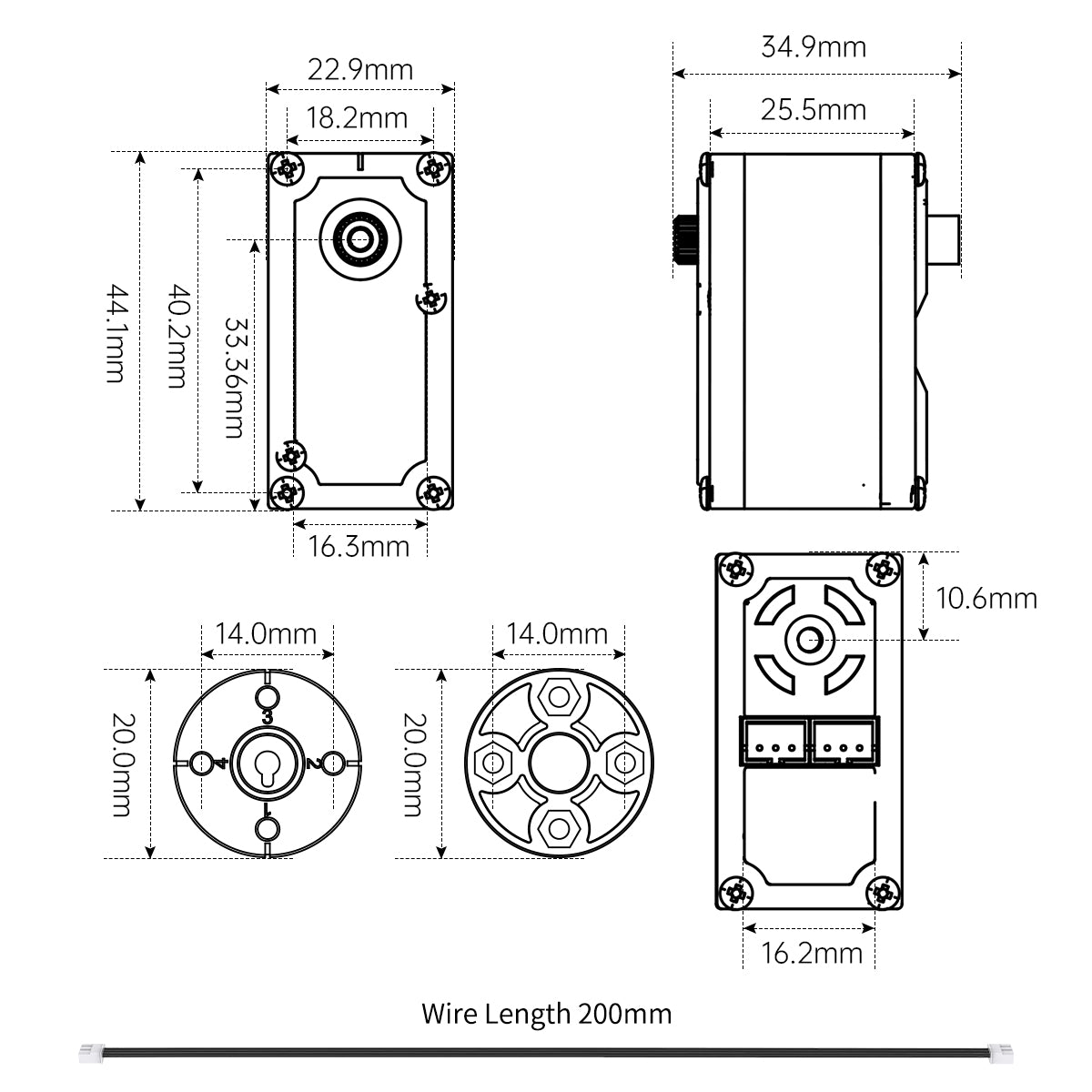

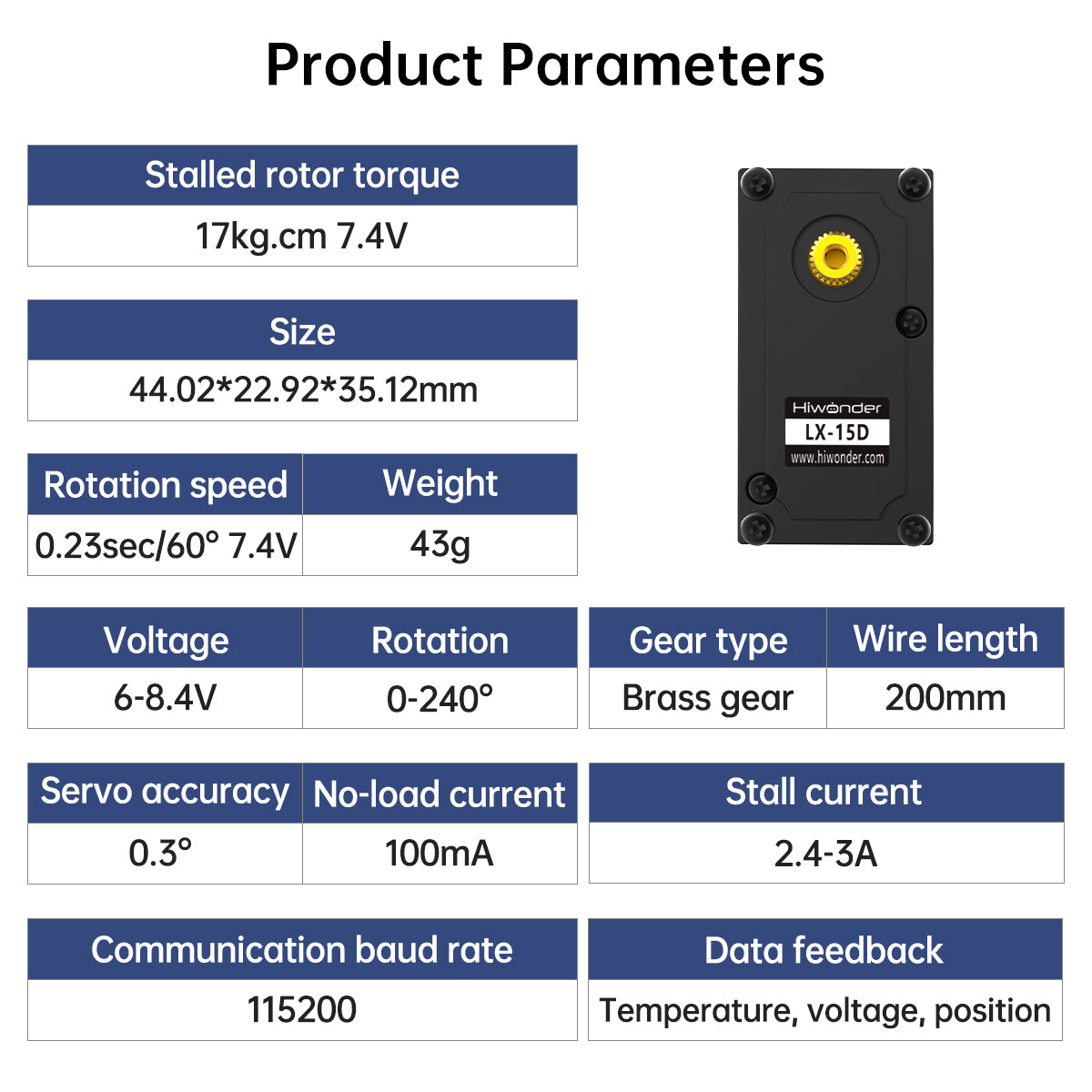

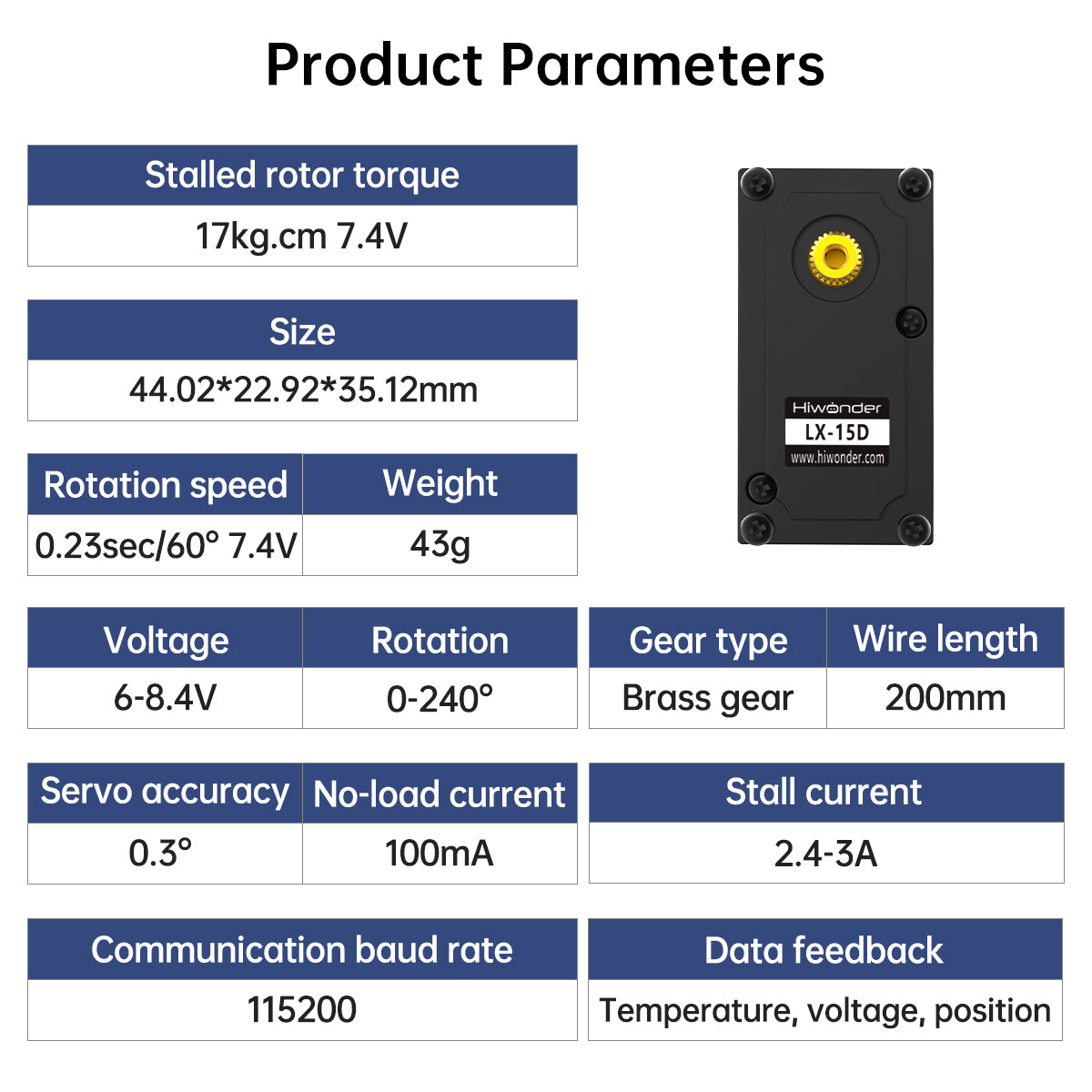

| Weight | 43g |

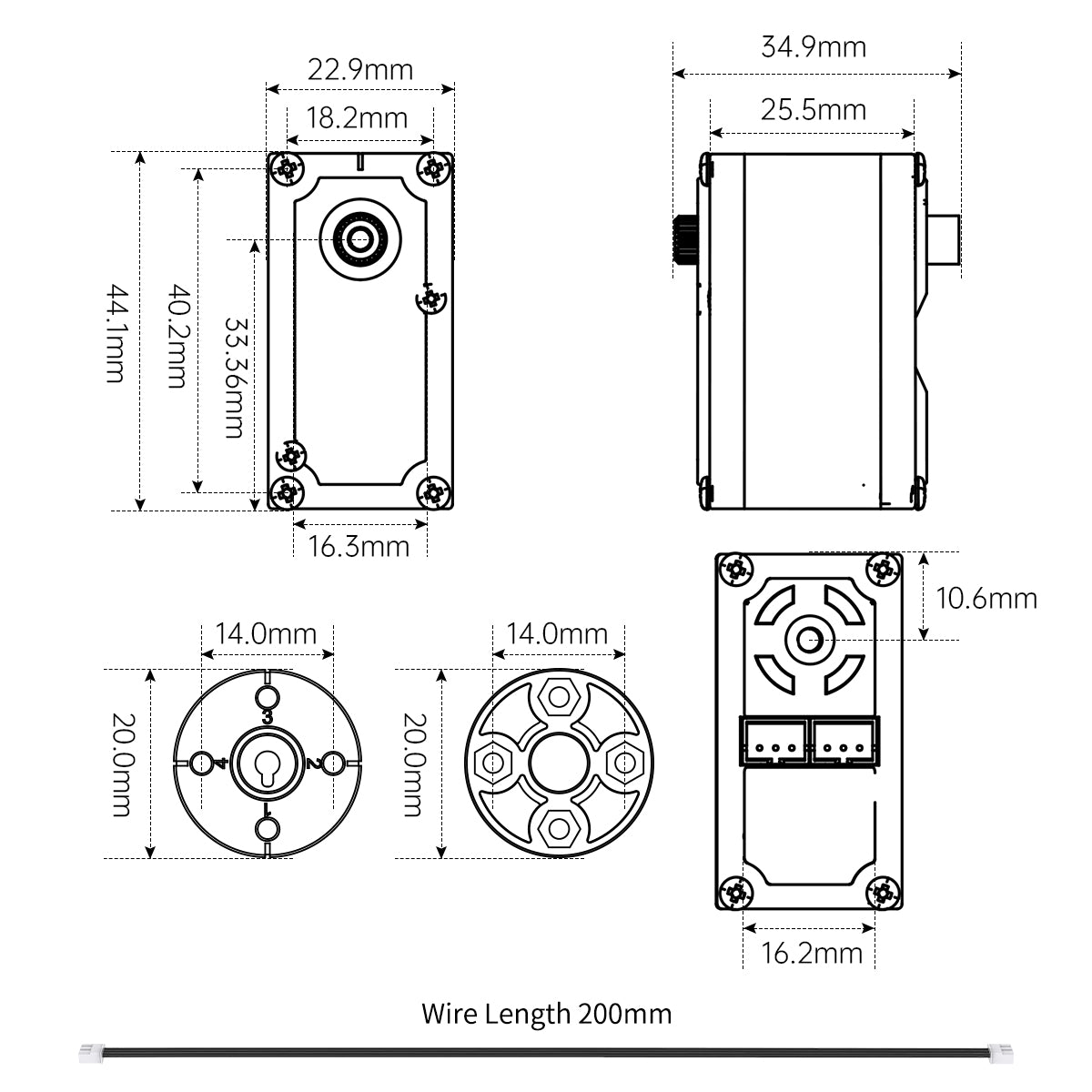

| Size | 44.02 x 22.92 x 35.12 mm |

| Working voltage | 6-8.4V |

| Speed | 0.22sec/60°7.4V |

| Torque | 15kg.cm 6V; 17kg.cm 7.4V |

| Rotation | 0-240° |

| No-load current | 100mA |

| Stall Current | 2.4~3A |

| Servo accuracy | 0.3° |

| Control method | UART serial command |

| Communication baud rate | 115200 |

| Storage | Save data when the power off |

| Servo ID | 0~253 for user setting, ID 1 is default |

| Angel read back function | Support |

| Protection | Avoid stalling and overheat |

| Data feedback | Temperature, Voltage, Position |

| Working mode | Servo mode and deceleration motor mode |

| Indicator | LED |

| Wire | 200mm |

| Gear | Metal |

Bus Servo Communication

The user can set and assign an ID number to each servo, and use the controller to issue instructions to make the servo perform actions according to the instructions.

High Torque and Strong Power

The servo has a maximum torque of 17kg.cm 7.4V, which is powerful and gives your robot plenty of power.

High Quality Potentiometer

The servo adopts a high-precision potentiometer, which improves the accuracy and linearity, makes the operation more stable and prolongs the service life.

Intelligent Feedback and Two Working Modes

The servo supports servo mode and reduction motor mode, and has position, temperature and voltage feedback to protect the normal operation of the servo.

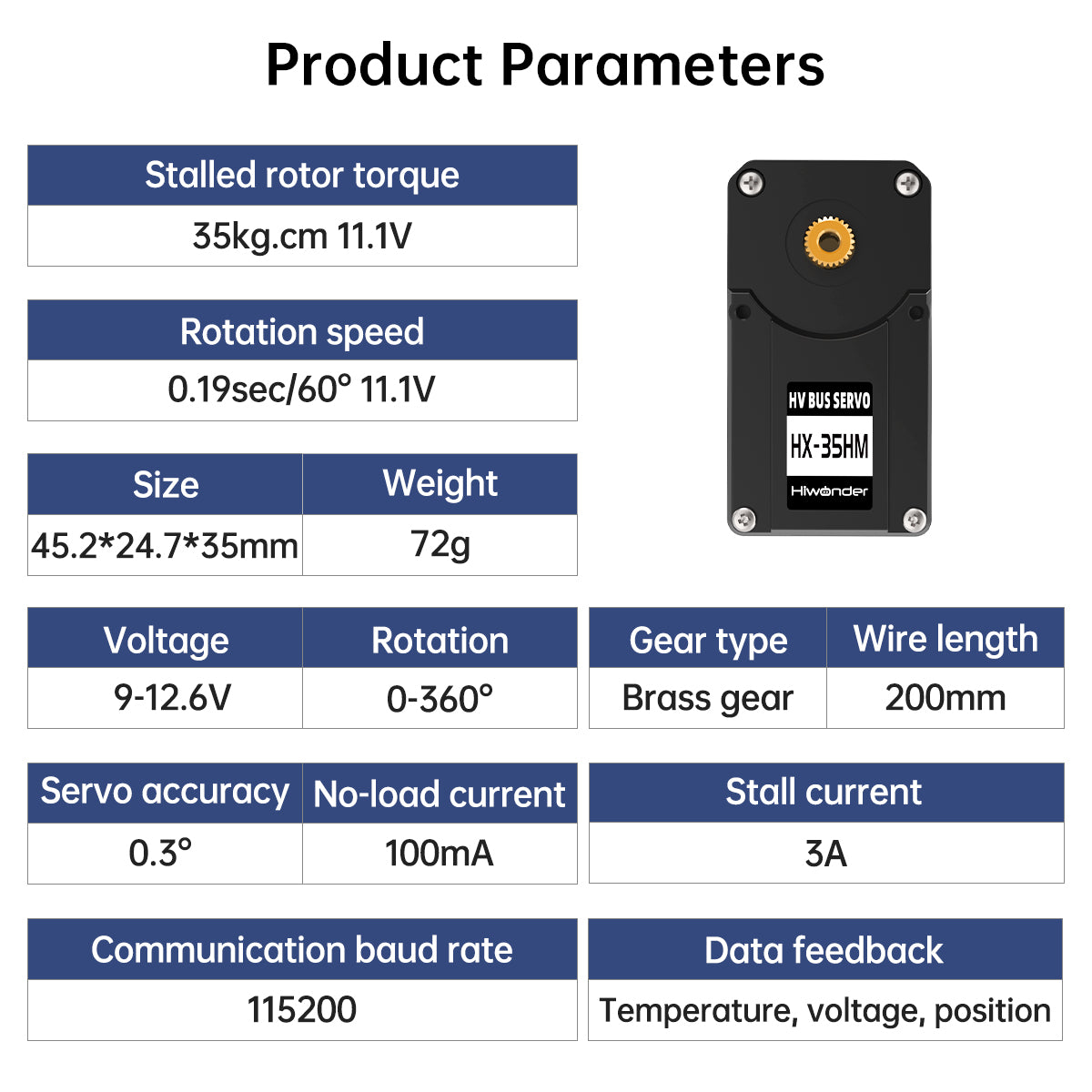

| Item | Specification |

| Weight | 43g |

| Size | 44.02*22.92*35.12mm |

| Working voltage | 6-8.4V |

| Speed | 0.22sec/60°7.4V |

| Torque | 15kg.cm 6V;17kg.cm 7.4V |

| Rotation | 0-240° |

| No-load current | 100mA |

| Stall Current | 2.4~3A |

| Servo accuracy | 0.3° |

| Control method | UART serial command |

| Communication baud rate | 115200 |

| Storage | Save data when the power off |

| Servo ID | 0~253 for user setting, ID 1 is default |

| Angel read back function | Support |

| Protection | Avoid stalling and overheat |

| Data feedback | Temperature, Voltage, Position |

| Indicator | LED |

| Working mode | Servo mode and deceleration motor mode |

| Control angle range | 0-1000, correspond to 0-240 |

| Wire | 200mm |

| Gear | Alloy gear |

In my experience with robotics, the Hiwonder LX-15D servo stands out as a reliable and versatile solution for robot joints. Its precise design not only enhances the visual appeal of my projects but also simplifies the wiring process, making integration smoother. The high-precision potentiometer for angle feedback ensures that I can achieve accurate and repeatable positioning in my robotic creations. The RGB indicator, coupled with temperature, voltage, and angle feedback, provides a comprehensive system for monitoring and protecting the servo from potential issues. The dual working modes—servo mode (0-240 rotation range) and gear motor mode (0-360 rotation range)—add to its versatility, making it suitable for various applications. The inclusion of metal gears significantly contributes to its durability, ensuring a longer service life even under demanding conditions. For anyone seeking precision, protection, and durability in their robotic joints, the LX-15D servo proves to be a reliable and indispensable component.

The integration of a high-precision potentiometer ensures that I have accurate angle feedback, crucial for achieving fluid and controlled movements. What sets this servo apart is its robust feedback system, like feedback on temperature, voltage, and angle. It is go-to choice for achieving versatility and durability in robotic joints.

LX-15D servo is a good choice for my robotic arm projects. The precision in its design not only enhances the aesthetics but also simplifies the wiring process, making it a breeze to integrate into my creations. Highly recommend for robotic projects!

This motor have sensibility to higher voltage, no protection if you have to high voltage. For beginner is good, to understand the ID of each motor with TTL network between motors. But no RS-485 solution. You don't have bigger motor with 100 or 200 kg/cm for torque. In reality you can't connect many motor on the same network, because you have limitation of Amp! You can find at Robotis solution to add power when you should use many big motor. This motor are good for beginner, but the resolution of encoder is limited and you don't have PID processus in each motor(Robotis have). It's better of PWM motor, but under Robotis motor, but the price is lower! The Hiwonder drive controler have time motion for each movement, you can simulate smoth movement. If you use this robot with ROS, you can have similar movement of ABB MoveL...

Haven't put them to use yet, still studying how to set the address. xArm makes a great third hand for soldering, assembly of other projects, as well as learning something about robotics.

Could be improved a lot with the capability to handle movement restrictions without damaging the servo, perhaps an overcurrent cutoff, max force control? Other devices are starting to have this capability.